Free-Air Sub Baffle Construction

And why stop at the dash Here's how I made my I-B baffle to house four 12" subs in a miniscule amount of space behind the rear seat in the civic.

MDF frame secured to "mounting base" to prevent baffle warpage during 'glassing

Before there was fleece in my hands...there was grille cloth! Easier to stretch, but nowhere near the strength once glassed, so you had to do many more layers of fiberglass to get it solid and thick

Resin applied

After multiple matting layers added to backside, the baffle was broken free of it's "supporting base", wood baffles cut out, and sanded

...and sanded...

Heres a test-fit showing the back "trunk-side" and all the fiberglass layers. This whole thing has a cross-sectional thickness of 3/4"!!!! That was a crapload of resin and mat.

Polyester filler primer and some dummy sub baskets for test fitting/trimming

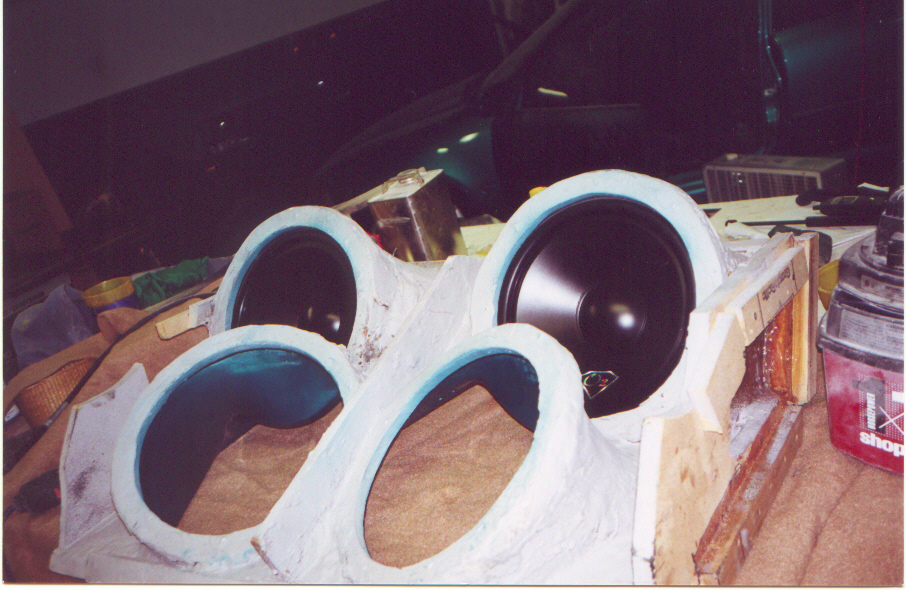

final subwoofer test fit with the subs

then in the car test-fitting

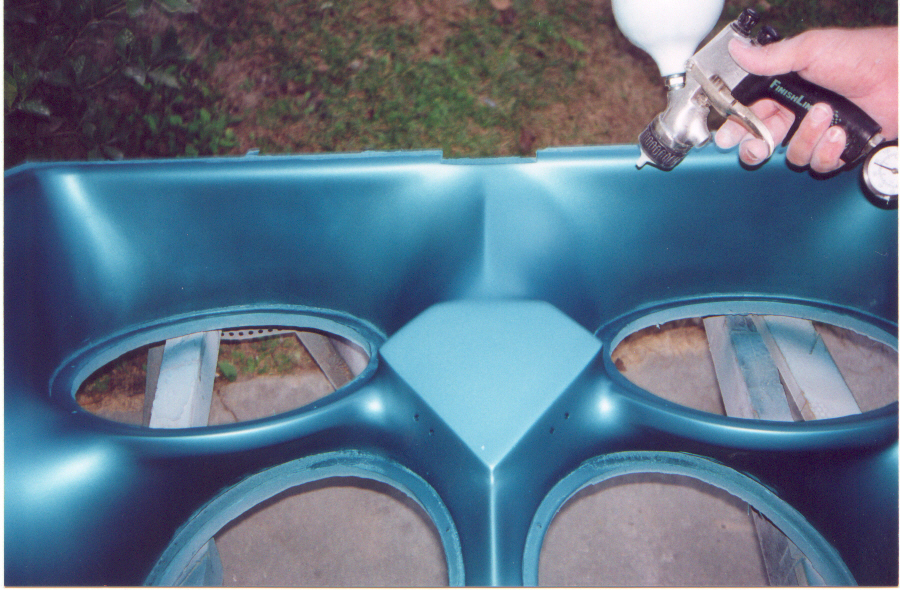

Base coat sprayed after wet-sanding the primer

Clearcoated, holographic sticker under clear, and subs bolted in.

Backside coated with spray Stinger Roadkill

close-up of finished install

Oh yeah, here is the making of the side and bottom bracework and sealing boards to provide a true Infinite Baffle by sealing off the trunk from the inside

More later...

© 2007 Audionizzle for Shizzle! All Rights Reserved. Site design and development by PyroPopTrt Designs.